Performance description:

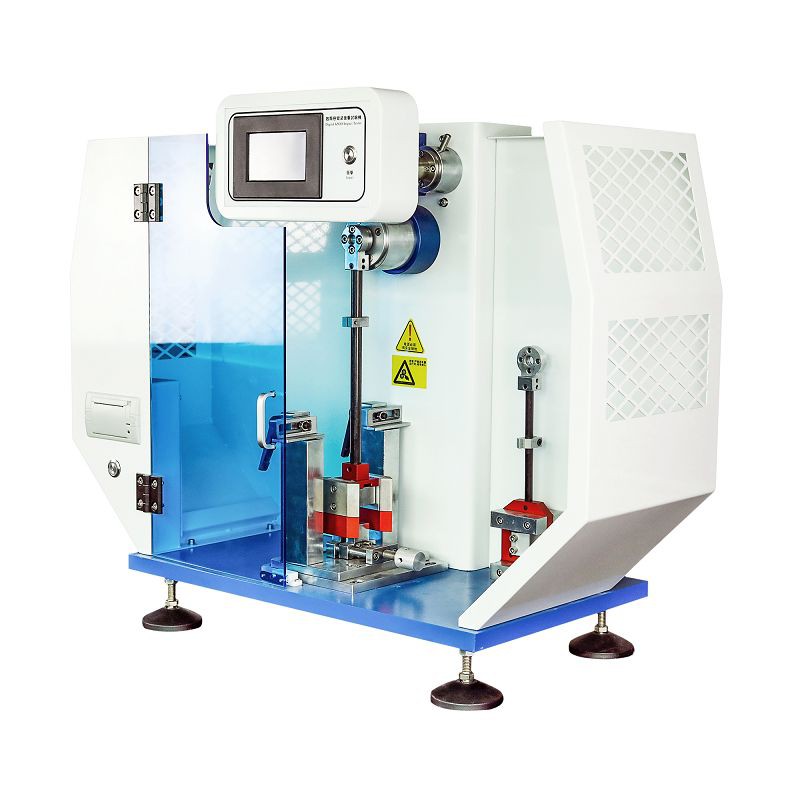

Impact testing machine is used to determine the resistance of metal materials to impact under dynamic load, so as to judge the quality of the material under dynamic load.

This machine is a semi-automatic control test machine with simple operation and high efficiency. It can control the pendulum, impact and pendulum electrical appliances, and can use the remaining energy after punching the sample to automatically pendulum to prepare for the next test, especially suitable for continuous operation. Impact test laboratory and metallurgy, machinery manufacturing and other industries that do a lot of impact tests. The B-type impact tester complies with the national standard GB / T3808-2002 "Inspection of Pendulum Impact Tester", and performs the impact test on metal materials according to the national standard GB / T229-2007 "Charpy Pendulum Impact Test Method for Metal Materials".

Technical characteristics:

1. The main machine of the testing machine has a single supporting column structure, a cantilever hanging pendulum, and a U-shaped pendulum body.

2. The impact knife is fixed by screws, which is easy to replace;

3. Sample simply supported beam support;

4. The main machine is equipped with safety protection pins and equipped with safety protection nets;

5. The testing machine is semi-automatically controlled. The pendulum, hanging pendulum, impact, and pendulum are all electrically controlled, and the remaining energy after punching the sample can be used to automatically prepare the pendulum for the next test. It is especially suitable for continuous impact. Test laboratory and a large number of metallurgy and machinery manufacturing departments doing impact tests;

6. The testing machine complies with the national standard GB / T3803-2002 "Inspection of Pendulum Impact Tester", and performs the impact test on metal materials according to the national standard GB / T229-2007 "Metal Charpy Notch Impact Test Method".

Technical indicators:

1. Impact energy: 300J (sledgehammer) 150 (small hammer)

2. Impact speed: 5.2m / s

3. Pre-lifting angle of pendulum: 150 °

4. Span of sample support: 40mm

5. Round corners of support jaw: R1.0 ~ 1.5mm

6. Fillet of impact blade: R2.0 ~ 2.5mm R8mm

7. The distance from the center of the pendulum to the impact point: 750mm

8. Standard sample size: 10 * 10 (7.5 or 5) * 55mm

9. Pendulum moment: M = 160.7695N.m 80.3848N.m

10. Power supply and power: 3phase 4line 50Hz 380V 180W

11. Dimensions: 2100 * 650 * 1900mm

12. Angle accuracy: 0.1 °

13. Weight: about 500Kg

Specifications:

Item | Charpy Impact | Izod Impact |

Pendulum energy | 1J, 2J, 4J, 5J | 1J, 2.75J, 5.5J |

Pendulum angle | 150° | |

Blade angle | 30° | |

Blade front angle | 5° | |

Blade back angle | 10° | |

Impact speed | 2.9m/s | 3.5m/s |

Impact center distance | 221mm | 335mm |

Blade filleted radius | R=2mm±0.5mm | R=0.8mm±0.2mm |

Energy loss | 0.5J ≤4.0J | 2.75J ≤0.06J |

Pendulum torque | Pd1J=0.53590Nm | Pd2.75J=1.47372Nm |

Print out | Capacity. Angle, energy, etc. | |

Power supply | AC220V±10% 50HZ | |

Pendulum energy | 1J, 2J, 4J, 5J | 1J, 2.75J, 5.5J |

Pendulum angle | 150° | |

Blade angle | 30° | |

Blade front angle | 5° | |

Blade back angle | 10° | |

Impact speed | 2.9m/s | 3.5m/s |

Impact center distance | 221mm | 335mm |

Blade filleted radius | R=2mm±0.5mm | R=0.8mm±0.2mm |

Energy loss | 0.5J ≤4.0J | 2.75J ≤0.06J |

Pendulum torque | Pd1J=0.53590Nm | Pd2.75J=1.47372Nm |

Print out | Capacity. Angle, energy, etc. | |

Power supply | AC220V±10% 50HZ | |

1. Customer inquiry process:

Discussing testing requirements and technic details, suggested suitable products to customer to confirm. Then quote most suitable price according to customer requirements.

2. Specifications customize process:

Drawing related drawings to confirm with customer for customized requirements. Offer reference photoes to show the proucts appearance. Then, confirm the final solution and confirm final price with customer.

3. Order process:

We offer below business term:

Accepted Delivery Terms: | FOB, CFR, CIF, EXW, DDP |

Accepted Payment Currency: | USD, EUR, HKD, CNY |

Accepted Payment Type: | T/T, L/C, Credit Card, PayPal, Western Union, Cash, Escrow |

Nearest Port: | Shenzhen, Guangzhou, Shanghai, Qingdao, Tianjing or rquired |

4. Production and delivery process:

We will produce the machines according to confirmed PO requirements. Offering photoes to show production process.

After finish production, offer photoes to customer to confirm again with the machine. Then do own factory calibration or third party calibration(as customer requirements). Check and test all the details and then arrange packing.

Deliver the products in confirmed shipping time and inform customer.

5. Installation and after sale service:

Defines installing those products in the field and providing after-sales support.

Standards:

ISO179-2000 "plastics - determination of impact strength of the simply supported beam with hard material

GB/T 21189 < plastic beam and cantilever beam and tensile impact test with a pendulum impact testing machine test >

GB/T1043-2008 "the hard plastic beam impact test method"

JB/T8762-1998 plastic beam impact testing machine

GB/T 18743-18743 "with thermoplastic fluid conveying pipe beam impact test method" (applicable to pipe)

ISO180-2000 "plastics - determination of hard material cantilever beam impact strength

GB/T1843-2008 "the hard plastic cantilever beam impact test method"

JB/T8761-1998 plastic cantilever beam impact testing machine

ASTM D256-2010 "test method for determination of plastic the IZOD pendulum impact strength,

GB - T13525-1992 "plastic tensile impact test method for performance"

Standard:

ISO179-2000, GB/T1043-2008, JB/T8762-1998, GB/T 18743-2002, ISO180-2000, GB/T1843-2008, JB/T8761-1998, ASTM D256-2010 ETC.

Hot Tags: charpy impact testing machine, China, suppliers, manufacturers, factory, buy, cheap, Metal Detector Machine, Portable Ultrasonic Thickness test Equipment, Rubber and plastic abrasion resistance tester, DIN Abrasion Resistance Tester, Ultrasonic Thickness Gauge, Din rubber abrasion tester